Follow us as we build our new Barn Pro’s barn!

PLEASE NOTE PHOTOS ARE COPYRIGHT 2020/2021/2022 CUTTER RIG PRODUCTIONS LLC ALL RIGHTS RESERVED

PLEASE ENJOY VIEWING BUT DO NOT DOWNLOAD, DISTRIBUTE OR REUSE WITHOUT WRITTEN PERMISSION FROM DOUG PICARD. doug@cutter-rig.com

THANK YOU AND ENJOY!!

The Old Barn

Old barn is gone! Sold for $4,000.

New barn getting delivered. Thank you San Lorenzo Lumber for providing a landing space.

San Lorenzo Lumber trans-shipped the individual pallets up to the farm.

Stacking and tarping.

Doing the layout.

Chris Goodenough drilling the holes.

Monte back shoveling the spoils.

Bob Travis from Travis Tree brought over his crane to set the posts.

The double sling was genius! Poles dropped straight down.

Plumb and square starting in the Northeast Corner as all Masons have before me.

Building the lego set!

Building it out. Measuring top and bottom and checking to be square.

Wood was a bit twisty so this part was challenging.

My brother Monte (on the left) and I knocking it out.

Almost done.

Double Sling.

Setting the last post. Dutch door support.

Forms for the side walls

Took 2 1/2 8 hour days to set the posts and check to make sure it was plumb and square. We're now ready for the posts & sidewalls concrete.

Here comes the concrete. No turning back!

Pumping the concrete! We added fiberglass flakes for extra strength.

Monte finishing.

Posts are set. Time to frame it out!

Lots and lots of measuring :-D You would think we were building a piano HaHa!

Monte set the first beams.

LVL's next. Monte is doing this by himself.

Getting ready for rafters.

Rafters going in.

Note the second beam set. My bad that I thought the pad was level. We had to compensate for a 2 foot drop in grade over 60 feet. Far posts were just not quite high enough.

Rafters Done.

Sheathing added.

Time for the LVL rafters.

Monte made a pocket for the end to sit in. That way he could set the LVL's by himself. I helped with the first two.

1st one set!

1st peak done

It's starting to look like a barn.

We lived through another day .

Monte setting the center set.

last set going up.

Building the pocket.

Hauling up the LVL.

Setting LVL in the pocket.

Lifting it up and setting on a cleat.

LVL rough set.

And done.

Purlin time!

Adding the sheathing as he goes.

Purlins are in!

Roof sheath is on.

Very nice lines :-D

Getting materials placed for the roofers!

(I watched)

Roofers starting at 8:30.

Working both sides at the same time.

Done by 1pm. 3 1/2 hours including a snack break. It was amazing to watch.

Nice peak in front. Note the rain channelers which was a very nice touch.

Perfect job. These guys were GOOD.

View from up the hill.

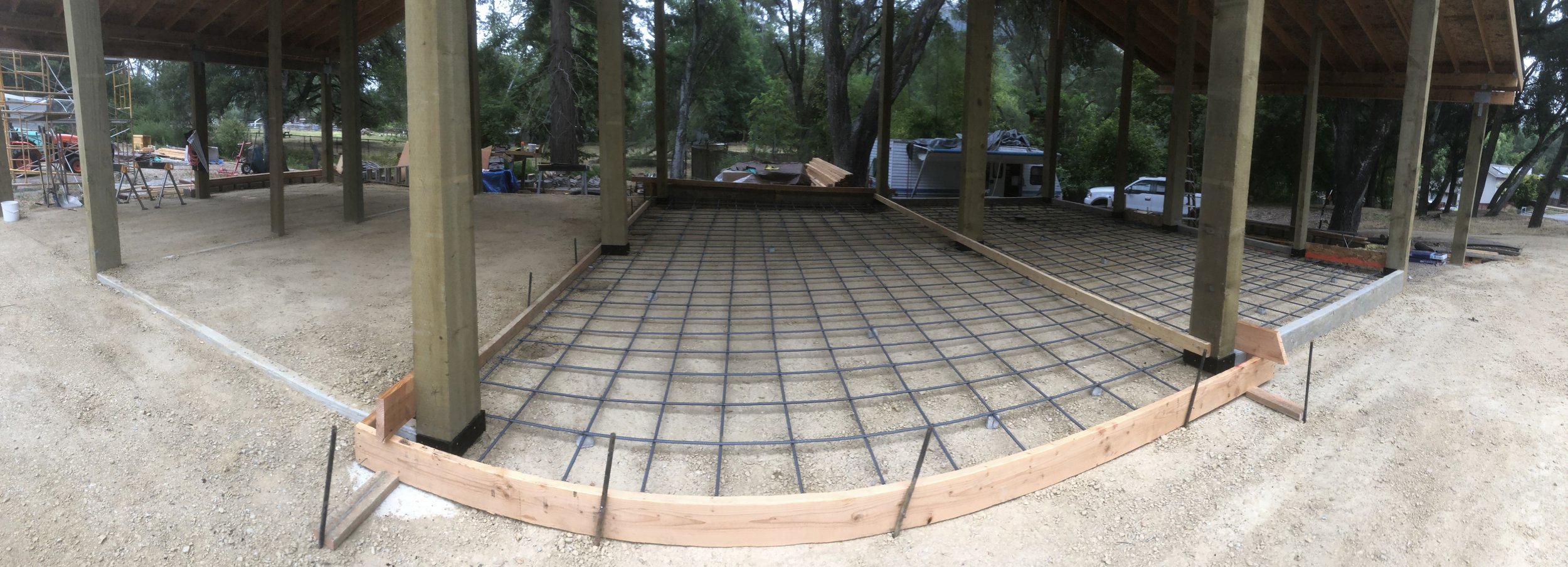

Fixing the grade inside. First the base rock.

Getting in the rebar

1/2" white is super strong

Tying in the sidewalls

You can see the drain for the wash rack

Ready to pump it up! See the black material around the posts. That allows for expansion keeping the concrete from cracking.

Pumping the floor.

Took 4 days before we could walk on it.

Framing for the breezeway doors and T1-11.

Almost ready!

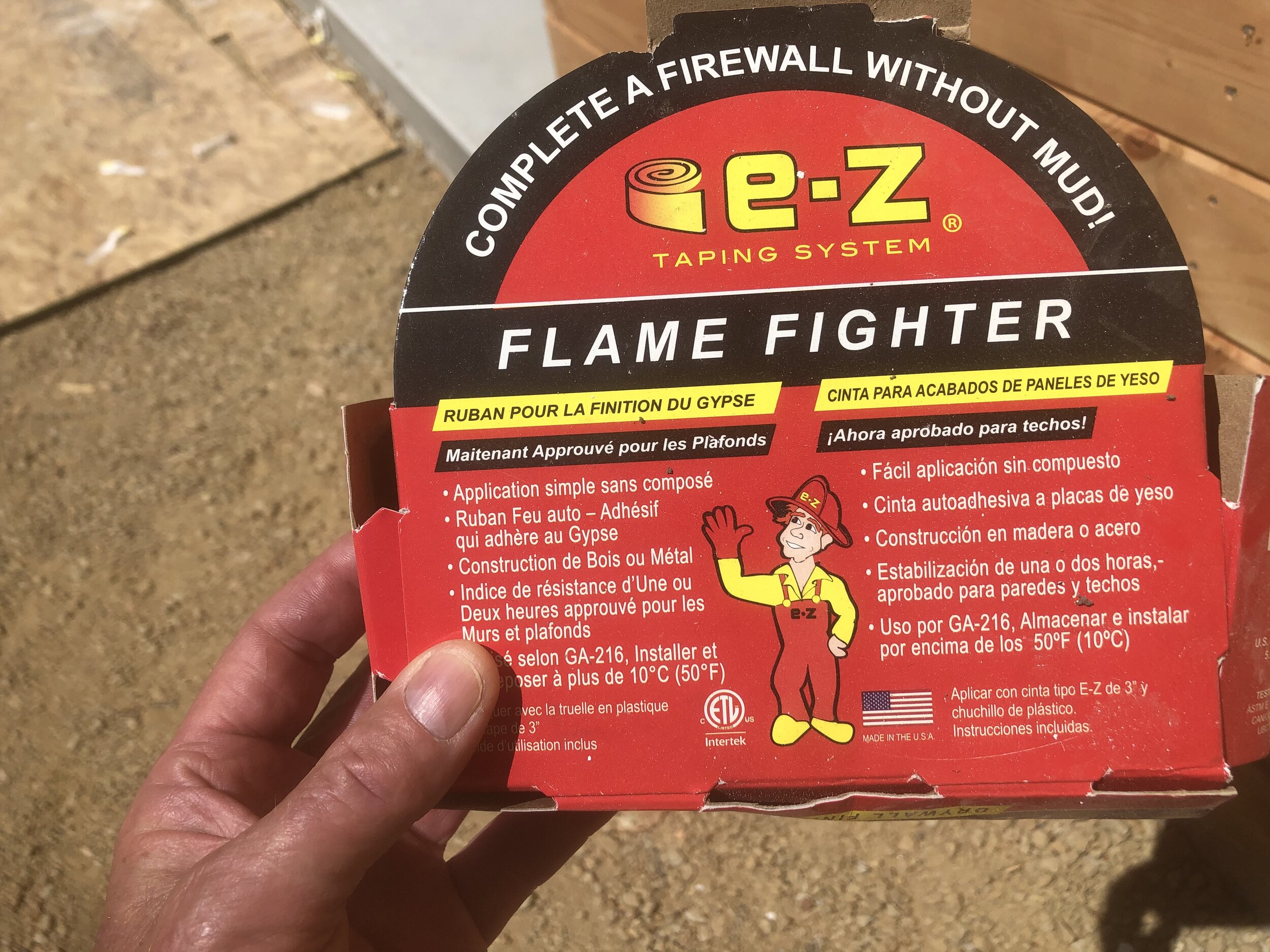

Taping is mud-less. Stuff is made of silicone.

Good stuff but expensive...

We live in a high fire zone so had to sheath in Densglass for a 1 hour fire rating.

Up goes the T&G!

We're starting to get excited.

This part went pretty quick.

Love the black flashing against the wood. Gorgeous! The T1-11 is African Mahogany!

1st breezeway door going up.

Wild fires in Santa Cruz smoking us out. We got evacuated and had to leave it. Hope it doesn't burn down. (fingers crossed)

We're back! Evacuation lasted 10 days. Everything was still here thank goodness. Second door going up!

Doors look good.

Here is where we are today, September 1st 2020

last section to button up! Then the dutch doors can go on

Dutch doors for the turnouts

Dutch door detail

Passed Inspection!! Yay!

Ready to start the first phase finishing work

Shot from my drone.

Getting in the stall mats. That's the buggy I race Lizzy with.

Ready for the stall fronts

Custom made in Wisconsin. Can't wait to open them up!

Super carefully packed

Do I need to say anything else?

They are heavier than I thought they would be.

Not a scratch so far :-D

Verrrry heavy...

Well we got them up in one day

Exceeded my expectations by far!

Heavy duty brass and stainless components

Starting to look like a real barn!! The equines can't wait to move in!

Nice solid stall divider

BIG bolts in the hinges. These stall components are super heavy duty

View from the driveway

It's a nice day when you're close to moving in the family

Our Dartmoor pony Lizzy is a champion driver

Simon is a thoroughbred race horse who is now living the retired life

Time to do the turnouts

I gated them on the outside in case we had to evacuate due to fire

Just about ready

We can get Lizzy out fast as well without having to go through the barn

Ready for pea gravel

Thats a lot of pea gravel to shovel around Wonder who is going to do that?

In it goes

Raked out and ready!

Pea gravel is excellent for the equine hoofs

Another day...

Hmm what's next? Let's put in utilities!

Rented a Ditch Witch

Bringing the power and water together in one trench Power is in conduit

Covering up the trench as we get the conduit and pipe laid to the sources

Power entrance

Water entrance has a shutoff

Placing the power panel

Stubbed out water

Building the tack room and adding the mezzanine for hay storage

Barn is already becoming a storage facility

12x12's 1 foot on center should carry the load

Roof over tack room for extra storage

Floor is in

Simon doesn't even look up

Adding the pull down ladder and sectioning off the hay elevator area

It's dark in here - need some lights

Pull down ladder is cool!

Let there be light!

Christmas wreaths on the outdoor carriage lights

March of 2022 lot of work into it so far and still more to go It's coming together!

Brother Monte and I enjoying a Proficiency Pilsner that I brewed up a few months back